Carbon fiber sheets are used in a wide range of applications where high strength and stiffness are required, combined with low weight. Some common uses of carbon fiber sheets include:

- Aerospace: used extensively in the aerospace industry, especially in the manufacture of aircraft components like wings, fuselage, and tail sections.

- Automotive: used in high-performance cars, such as racing cars and supercars, for body panels and other structural components, to reduce weight and improve performance.

- Sports: used in sports equipment, such as tennis rackets, golf clubs, and bicycles, to make them lighter and stiffer, which can improve performance.

Overall, carbon fiber sheets are valued for their high strength, stiffness, and low weight, making them ideal for applications where these properties are essential.

All sheets are shipped in the “raw carbon” state — there is no clear coat or gel coat applied.

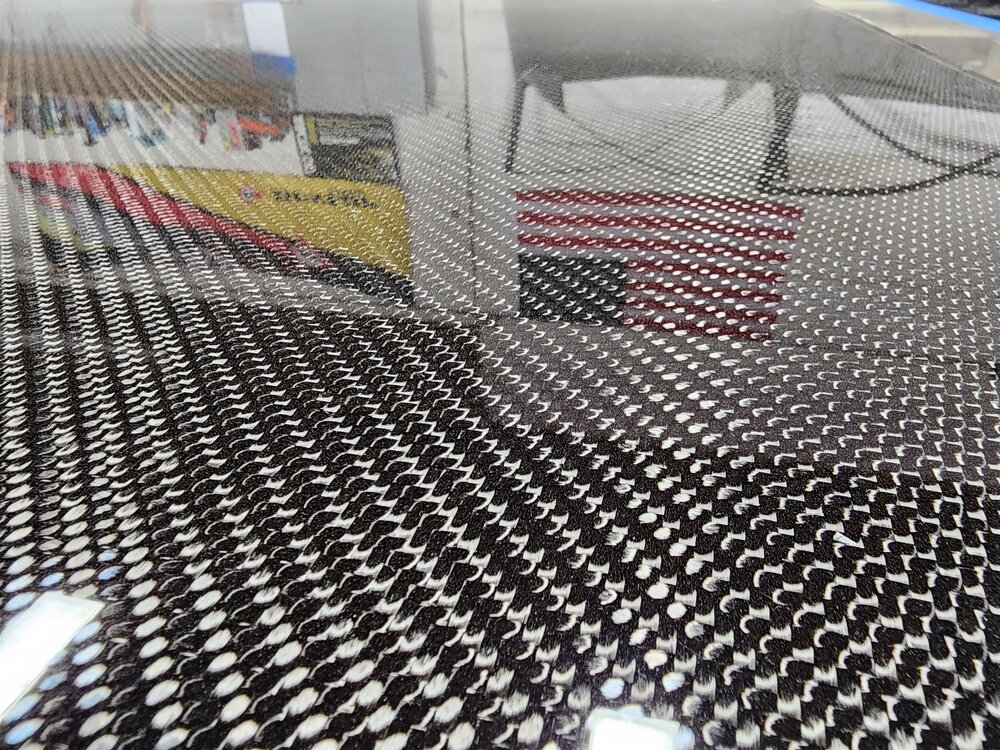

Carbon Fiber Sheet Options (Carbon Style)

- 2×2 Twill — Lightweight carbon fiber sheets backed with Innegra (like Kevlar) manufactured using vacuum infusion

- Forged — The process involves placing carbon fibers into a mold and then infusing resin into the mold. The result is a material with a unique, marbled appearance that is stronger (in all directions) than traditional carbon fiber. Note that forged sheets can not be rolled up in a tube and requires custom freight shipping.

- Pre-preg — The term “pre-preg” is short for “pre-impregnated,” which means that the matrix material has already been applied to the carbon fiber in a controlled manufacturing process, and the material is ready for use.

- Economy — These carbon fiber sheets include one layer of carbon on the aesthetic or “pretty” side and are backed by one layer of fiberglass for extra rigidity.

Sold by the sheet and proudly made in the USA.

All sheets will have a oversize fee of $70.00 when shipped via ground delivery to the contiguous 48 United States; forged will require a custom freight quote as it cannot be rolled.